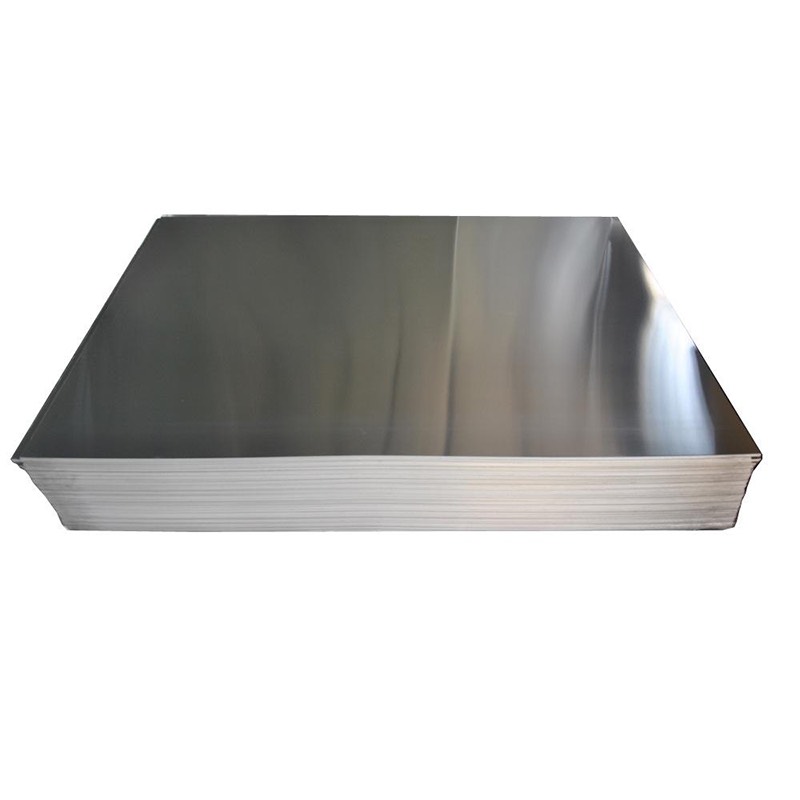

5052 Aluminum Sheet

- Thickness: 0.5mm-170mm

- Width: Under 2250mm

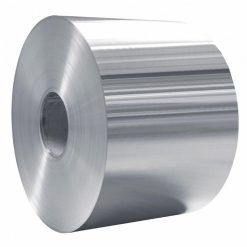

- Length:Under 11000mm(11m) or by coil.

- rief Introduction for Aluminum 5052Aluminum 5052 has high corrosion resistance, so it’s widely used in marine industry and saltwater. It’s a medium to high strength alloy, higher than 5251, 1100, 3300 aluminum alloy. Aluminum 5052 has high machinability and fatigue strength. 5052 also has other common trade names. They are UNS A95052 in ASTM B209, EN AW-5052 (AlMg2.5), 3.3525 etc. These names are aluminum 5052 equivalents.5052 aluminum sheet from Henan Wanda is usually sold to the North America like America, Canada, Mexico (usually are aluminum 5052 coil) etc., Southeast Asia like Vietnam, Thailand, Malaysia and Singapore, Indonesia etc., European countries like Russia, Croatia, France, Italy, Switzerland, Germany, England etc. Usually for curtain wall and oil tank materials.

What Is 5052 Aluminum Used For?

5052 aluminum can be used in seawater and salt spray environment. So we know that it’s used as marine aluminum plate. For example, the tanks of natural gas tankers. 5052 aluminum can be also used in building facade in architecture field. In transportation field, 5052 aluminum has many applications like aircraft, bus, and truck manufacturing, road and name signs, fuel lines and tanks, streetlights etc. Especially for lightweight automobile.

Applications of thin 5052 aluminum sheet include: 3C products, computer brackets, high-end curtain wall panels, high-end oxide materials, aluminum can body and can end, shutters, trolley cases, aluminum furniture, door panels and door handles, signs etc.

The uses of 5052 aluminum plate are: silo, flange material, GIS shell, yacht, underwear mold, shoe mold, gas storage tank, mask machine, mask machine, precision machining etc.

Is 5052 Aluminum Sheet Bendable?

Bending process has different types, for example, roller bending, press bending, draw bending and stretch bending. I suggest you to know about what affects bending before choosing aluminum alloy and bending process.

As I know, there are three factors that affect bending. The first one is formability. Generally, when an aluminum alloy has higher strength, it’s more difficult to be bent. The second factor is thickness and bend radius. Last one is percentage of elongation. large range means good formability.

So, is 5052 aluminum sheet bendable? Yes, it is. Even though aluminum 5052 is not as good for bending as 3003, it’s still a good choice. In some situation, 6000 series aluminum alloy are also bendable, like aluminum 6063. If you need an aluminum alloy for bending, my first suggestion is aluminum 3003. Next one is aluminum 5052. But aluminum 5052 has high strength and excellent corrosion resistance. After annealing, 5052 has higher formability than 3003 aluminum. Then I recommend aluminum 5083. The last are 6061 and 6082 aluminum. One point, temper is as important as alloys to bending. For 3000 series and 5000 series aluminum alloy, O temper is the best choice for bending.

Aluminum 5052 Corrosion Resistance

You may wonder, is aluminum 5052 corrosion resistant? The answer is yes. And aluminum 5052 has high corrosion resistance. Why? The reasons are complicated. As I know, temperature, chemicals in the air and the environment determine the degree of corrosion. 5052 does not contain any copper, so it’s widely used in seawater environment, like ships, boats etc. The corrosion resistance of aluminum alloy is affected by the protective oxide film on the surface. We can use anodizing and protective layer coating to improve the corrosion resistance of aluminum 5052.

Aluminum 5052 vs 6061, 3003, 7075

Do you know the differences between aluminum 5052 and 6061? In a word, the biggest difference of the two alloys is that aluminum 6061 has excellent heat treatability while aluminum 5052 is not heat-treatable. 6061 is stronger than 5052. Aluminum 5052 is soft so it’s difficult to be machined. But aluminum 6061 is harder than 5052, it’s easier to be machined. There is a web from our trading company- Henan Climb. It has a table that you can see the difference more intuitively, and the table also contains 7075 alloy.

What about the difference of aluminum 5052 and 3003? Simply speaking, aluminum 5052 has higher strength and corrosion resistance than aluminum. If you attach great importance to the two points, I suggest you choose aluminum 5052. If not, aluminum 3003 is cheaper, you can choose 3003 too. Here is a YouTube video, you can understand their difference more clearly.

5052 Aluminum Gauge Chart and Weight Calculator

Many people search on Google for the 5052 aluminum gauge chart in order to know about aluminum thickness among gauge, inch and millimeter. Here is a chart I write. It’s only for aluminum alloy. If you look for chart for steel or stainless steel, it doesn’t work. The chart is just for your reference.

Besides, some customers are not so clear about what weight is the aluminum alloy they need. They only have a pcs list. Here is a website you can calculate the weight. In the left side, check the aluminum alloy you need, choose the shape you want, then input the dimensions: length, width and thickness and the number of metal pieces. The result is the weight you need. You got it?

5052 Aluminum Gauge Chart

Gauge (ga) Aluminum Thickness (in.) Aluminum Thickness (mm) 3 0.2294 5.83 4 0.2043 5.19 5 0.1819 4.62 6 0.162 4.11 7 0.1443 3.67 8 0.1285 3.26 9 0.1144 2.91 10 0.1019 2.59 11 0.0907 2.3 12 0.0808 2.05 13 0.072 1.83 14 0.0641 1.63 15 0.0571 1.45 16 0.0508 1.29 17 0.0453 1.15 18 0.0403 1.02 19 0.0359 0.91 20 0.032 0.81 21 0.0285 0.72 22 0.0253 0.64 23 0.0226 0.57 24 0.0201 0.51 25 0.0179 0.45 26 0.0159 0.4 27 0.0142 0.36 28 0.0126 0.32 29 0.0113 0.29 30 0.01 0.25 31 0.0089 0.23 32 0.008 0.2 33 0.0071 0.18 34 0.0063 0.16 35 0.0056 0.14 Typical Properties Datasheet of 5052Aluminum and Its Tempers

Strength (KSI) Elongation % in 2 In. Alloy & Temper Ultimate Min. – Max. (KSI) Yield Set 0.2% 1/16” Thick ½” Dia. Brinell Hardness 5052-0 25 – 31 13 25% 30 47 5052-H32 31 – 38 28 12% 18 60 5052-H34 34 – 41 31 10 14 68 5052-H36 37 – 44 35 8% 10 73 5052-H38 39 – – 37 7% 8 77 These are only some typical properties just for your reference.